| Machine features |

|---|

Convenient control of the CNC system. Ability to select manual control, semi-automatic, use of CNC functions

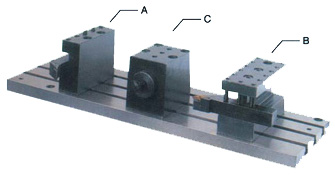

Additional mounting plate is designed for cutting tools. Designed specifically for the different complexity of treatments without additional time spent on tool changes and without additional indexing, it greatly helps save time for machine processing. The system is user friendly, suitable for fast, accurate, efficient milling, drilling, and thread cutting.

Hard high speed spindle. The spindle is equipped with 5-mA angular thrust bearings, allowing to provide resistance to hard metal removal.

High precision spindle. Equipped with double high precision roller and angular contact thrust bearings.

High-speed and high-precision turret head. Operated by hydraulics and clutch. The possibility of rotation in both directions. The time for a standard tool change to 0.2 seconds.

The driving turret provides multi-purpose machining - milling, threading, drilling. 8-12 tools. The rotation range is 25-4000 revolutions per minute.

| Parameters/Model | Unit | ANC-10 | ANC-10A | ANC-15 |

|---|---|---|---|---|

| Diameter over bed / plate | mm | 400/120 | ||

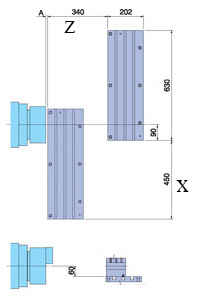

| Mounting plate length | mm | 630 | ||

| Chuck diameter | mm | 160 | 210 | 254 |

| Spindle shank | A2-5 | A2-6 | A2-8 | |

| Spindle bearing diameter | mm | 90 | 100 | 130 |

| Spindle bore diameter | mm | 56 | 62 | 87 |

| Bar diameter | mm | 45 | 52 | 75 |

| Spindle cone | MT6 | 1:20 | 1:20 | |

| Spindle speed | rpm | 400-4000 | 400-4000 | 32-3200 |

| Z axis carriage travel | mm | 340 | ||

| Cross slide travel по оси X | 450 | |||

| X axis rapid travel | m/min | 15 | ||

| Z axis rapid travel | m/min | 15 | ||

| Toolholder inner diameter | mm | 40 | ||

| The external size of the tool holder | mm | 20 | 25х25 | 25х25 |

| Bed width | mm | 560 | ||

| Bed angle | mm | 45° | ||

| Spindle motor power | kw | 18ip AC9 | 18ip AC9 | 22ip AC9 |

| X axis servo motor power | kw | 1.8 | 1.8 | 1.6 |

| Z axis servo motor power | kw | 1.8 | 1.8 | 3.0 |

| Hydraulic pump drive power | kw | 0.75 | ||

| Hydraulic pump drive power | kw | 0.375 | ||

| Hydraulic pump drive power | w | 25 | ||

|

Machine weight (gross) |

kg | 3500 | 3500 | 3800 |

| Machine size (LxWxH) | mm | 2920х1810х2100 | 2920х1810х2100 | 3230х1810х2100 |

| Parameters/Model | Unit | ANC-20A/AL | ANC-30N/NL | ANC30N x 1650/2150/2650 |

|---|---|---|---|---|

| Swing over bed | mm | 460 | 640 | 600 |

| Diameter over cross slide | mm | 280 | 430 | |

| Distance between centers | 460/660 | 670/1150 | 1730/2230/2730 | |

| Cut diameter | mm | 270-straight type 220- VDI |

480-straight type 440- VDI |

|

| Diameter of hydraulic chuck | mm | 210 | 254 | |

| Bar diameter | mm | 52/65 (option) | 75 | |

| Bed width | mm | 360 | 480 | |

| Bed angle | 30° | 45° | ||

| Spindle shank | A2-6 | A2-8 | ||

| Spindle bore diameter | mm | 62/75 (option) | 87 | |

| Spindle cone | 1/20 | |||

| Spindle speed | rpm | 40-4000 | 32-3200 | |

| Spindle motor power | Fanuc 18ip 9 kw | Fanuc 22ip 11 kw | Fanuc 18ip 18.5 kw | |

| Outside spindle diameter | mm | 100 | 130 | |

| Turret type | Hydraulic/Servo (option) | |||

| Number of turret positions | 8 | 10/12(option) | ||

| Tool size | mm | 25х25 | ||

| X axis travel | mm | 150 | 255 | |

| Z axis travel | 400/640 | 610/1090 | 1650/2150/2650 | |

| X axis rapid travel | m/min | 15 | 18 | 15 |

| Z axis rapid travel | m/min | 15 | 18 | 15/12/7 |

| Toolholder inner diameter | mm | 32 | 40 | |

| Moving tailstock | mm | 240/480 | 500/980 | 1560/2060/2560 |

| Quill travel | mm | 80 | 100 | |

| Quill diameter | mm | 70 | 110/160 (option) | |

| Quill cone | MT4 | MT4/MT5 (option) | ||

| X axis servo motor power | kw | 1.8 | 3.0 | |

| Z axis servo motor power | kw | 1.8 | 3.0 | |

| Hydraulic pump drive power | kw | 1.5 | ||

| Coolant pump drive power | kw | 0.37 | ||

| Power consumption | kva | 22 | 30 | 40 |

| Lead screw diameter X axis | 32 | |||

| Lead screw diameter Z axis | 36 | 40 | 50 | |

| Machine weight (gross) |

kg | 4000/4600 | 5500/6500 | 8200/9400/10600 |

| Machine size (LxWxH) | mm | 3130/3350x2000x2050 | 4000/4550x2090x2250 | 5100/5800/6500x2090x2250 |

| Parameters/Model | Unit | ANC-40N/NL | ANC-40N x 1650/2150/2650 |

|---|---|---|---|

| Swing over bed | mm | 640 | 600 |

| Diameter over cross slide | mm | 430 | |

| Distance between centers | 670/1150 | 1715/2215/2715 | |

| Cutting diameter | mm | 480-straight type/440- VDI | |

| Hydraulic chuck diameter | mm | 304/380 (option) | |

| Bar diameter | mm | 90 | |

| Bed width | mm | 480 | |

| Bed angle | 45° | ||

| Spindle shank | A2-8 | ||

| Spindle bore diameter | mm | 102 | |

| Spindle cone | 1/20 | ||

| Spindle speed | rpm | 10-2500 | |

| Spindle motor power | kw | Fanuc 18ip 18.5 kw | |

| Spindle outer diameter | mm | 160 | |

| Turret type | Hydraulic/Servo (option) | ||

| Number of turret positions | 10/12(option) | ||

| Tool size | mm | 25х25 | |

| X axis travel | mm | 255 | |

| Z axis travel | 610/1090 | 1650/2150/2650 | |

| X axis rapid travel | m/min | 18 | 15/15/15 |

| Z axis rapid travel | m/min | 18 | 15/12/7 |

| Toolholder inner diameter | mm | 40 | |

| Rear tailstock travel | mm | 500/980 | 1560/2060/2560 |

| Quill travel | mm | 100 | |

| Quill diameter | mm | 110/160 (option) | |

| Quill cone | MT4/MT5 (option) | ||

| X servo motor power | kw | 3.0 | |

| Z axis servo motor power | kw | 3.0 | 4.0 |

| Hydraulic pump motor power | kw | 1.5 | |

| Coolant pump motor power | kw | 0.37 | |

| Power consumption | kva | 40 | |

| Lead screw diameter X axis | 32 | ||

| Lead screw diameter Z axis | 50 | ||

| Machine weight (Gross) |

kg | 6000/7000 | 8200/9400/10600 |

| Machine size (LxWxH) | mm | 4000/4550x2090x2250 | 5100/5800/6500x2090x2250 |

| Parameters/Model | Unit | ANC-40NE x 650/1150 | ANC-40NE x 1650/2150/2650 |

|---|---|---|---|

| Swing over bed | mm | 800 | 750 |

| Diameter over cross slide | mm | 590 | |

| Distance between centers | 670/1150 | 1715/2215/2715 | |

| Hydraulic chuck diameter | mm | 310/380,450 (option) | |

| Bar diameter | mm | 90/117.5, 140 (option) | |

| Bed width | mm | 480 | |

| Bed angle | 45° | ||

| Cut diameter | mm | 720-straight type/650- VDI | |

| Spindle shank | A2-8/A2-11 (option) | ||

| Spindle bore diameter | mm | 102/160 (option) | |

| Spindle cone | 1/20 | ||

| Spindle speed | rpm | 10-2500/10-1650 (option) | |

| Spindle motor power | kw | Fanuc 18ip 18.5 кВт | |

| Outside spindle diameter | mm | 160/220 (option) | |

| Turret type | Hydraulic/Servo (option) | ||

| Turret number of positions | 10/12(option) | ||

| Tool size | mm | 25х25 | |

| X axis travel | mm | 360 | |

| Z axis travel | 610/1090 | 1650/2150/2650 | |

| X axis rapid travel | m/min | 18 | 15/15/15 |

| Z axis rapid travel | m/min | 18 | 15/12/7 |

| Toolholder inner diameter | mm | 40 | |

| Rear tailstock travel | mm | 500/980 | 1560/2060/2560 |

| Quill travel | mm | 100 | |

| Quill diameter | mm | 160 | |

| Quill cone | MT5 | ||

| X axis drive motor power | kw | 3.0 | |

| Z axis drive motor power | kw | 3.0 | 4.0 |

| Hydraulic pump motor power | kw | 1.5 | |

| Coolant pump motor power | kw | 0.37 | |

| Power consumption | kva | 40 | |

| Lead screw diameter по оси X | 32 | ||

| Lead screw diameter по оси Z | 50 | ||

| Machine weight (Gross) |

kg | 6300/7300 | 8500/9700/10900 |

| Machine size (LxWxH) | mm | 4000/4550x2250x2250 | 5100/5800/6500x2250x2250 |

| Standart systems and accessories/Model: ANC-10,10A,15 | |

|---|---|

| - Hollow hydraulic chuck 6",8",10" Cylindr | - Coolant system, automatic lubrication system |

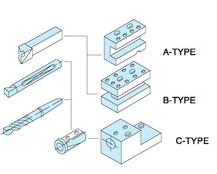

| - Tool holder type А,B,C | - Transformer 380 V |

| - Center adapter, diameter 8,10,12,16,20,25,32 |

- Working light |

| - Adapting plate | - Chip Conveyor |

| - Tool box | - Manual operation |

| Standart systems and accessories/Model: ANC-20A/AL/30N/NL/40N/NL/40NE | |

| - Hollow hydraulic chuck cylinder | - Center adapter, diameter 8,10,12,16,20,25,32 |

| - Hydraulic turret, adapter mandrels | - Chip conveyor |

| - Hydraulic tailstock for ANC-20A series | - Transformer 380 V |

| - Hydraulic programmable tailstock for the ANC-30N series | - Working light |

| - Coolant system, hydraulics | - Tool box |

| Additional options/Model: ANC-10,10A,15 | |

|---|---|

| - Spindle indexing 15° | - Bar feeder |

| - Chuck cleaning device | - Bar unloader |

| - Finished parts catcher | - Automatic door |

| - Additional mandrels | - Optional adapter plate |

| - Устройство для фрезерования | - Collet chuck |

| - Voltage regulator | - Cutting, auxiliary tool |

| Additional options/Model: ANC-20A/AL/30N/NL/40N/NL/40NE | |

| - Bar feeder | - Tool presseter |

| - Finished parts catcher | - Additional tool holder |

| - C-axis, spindle indexing with drive turret | - Optional adapter plate |

| - Tool holder for VDI | - CE |

| - Voltage stabilizer | - Cutting, auxiliary tool |