| Machine description |

|---|

|

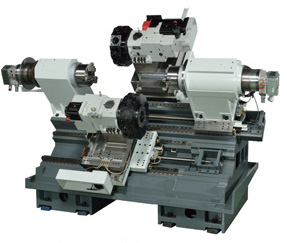

HIGH-SPEED MULTI-FUNCTIONAL LATHE CNC MACHINES SERIES ANC-N210 WITH TWO SPINDLES, TWO REVOLVING HEADS, TWO AXES, C, Y The equipment has a counter-spindle that allows for maximum automation of production, and at the same time provides a significant increase in productivity. The presence of two spindles in the machines allows you to achieve the maximum level of automation and achieved performance. The workpiece is automatically transferred from one spindle to another - the whole process is fully automatic. Two spindles also allow simultaneous processing of two workpieces at once, thus increasing the capacity of the equipment at once by two times. With all this, the cost of one piece of equipment will be significantly lower than the cost of two similar machines with one spindle. This equipment design is specially designed for blanks with complex machining parameters.

|

| Machine features |

|---|

| Parameters/Model | Unit | ANC-210DS | ANC-210DT | ANC-210DST |

|---|---|---|---|---|

| Swing over bed | mm | 850 | ||

| Diameter over cross slide | 540 | |||

| Maximum machining diameter | mm | 520 | ||

| Maximum processing length | mm | 700 | ||

| Spindle shank (left) | A2-6 | |||

| Spindle bore | mm | 62 | ||

| Bar diameter | mm | 52 | ||

| Spindle bearing inner diameter | mm | 100 | ||

| Diameter of hydraulic chuck | mm | 210 | ||

| Spindle speed | rpm | 40-4500 | ||

| Spindle shank (right) | A2-6 | - | A2-6 | |

| Spindle bore | mm | 62 | - | 62 |

| Bar diameter | mm | 52 | - | 52 |

| Spindle bearing inner diameter | mm | 100 | - | 100 |

| Diameter of hydraulic chuck | mm | 210 | - | 210 |

| Spindle speed | rpm | 40-4500 | - | 40-4500 |

| E axis travel (tailstock) | mm | 700 | 700 | |

| E axis rapid speed travel | m/min | 20 | 20 | |

| Tool head / collet ER | 12 (BMT65)/(ER32) | |||

| Axis travel | mm | X1:260 Z1:600 |

X1:260/X2:190 Z1:600/Z2:600 |

|

| Turret drive power | kw | 3.5/5.5 | ||

| Turret rotation speed | rpm | 5000 | ||

| Rapid speed travel | m/min | X1/X2: 20 |

||

| CF axis rapid travel | rpm | 83 (option) | ||

| Tool size | mm | 25х25,ø40 | ||

| Moving tailstock | mm | - | 700 | - |

| Quill travel | mm | - | 100 | - |

| Quill diameter | mm | - | 100 | - |

| Quill cone | - | MT4 | - | |

| Main spindle motor | kw | Fanuc aiiP 22/6000 (11/15) | ||

| Counter spindle motor | kw | Fanuc Bil 170S/6000 (11/15) | ||

| Axis drivers | kw | X1/Z1/Z2/Y2/E: ail12 (3.0) X2/Y2: ail22 (4.0), Cf: aii8 (1.6) |

||

| Hydraulic pump drive power | kw | 2.2 | ||

| Coolant pump drive power | 1.5 | |||

|

Machine weight (gross) |

kg | 7500 | 8500 | 9200 |

| Dimensions of the machine (LxW) | mm | 4733 х 2202 х 2300 | ||

| Standart systems and accessories | |

|---|---|

| - Hydraulic hollow chuck cylinder | - Air and water gun |

| - Counter spindle refrigerator | - Chip conveyor (right side) |

| - Hydraulic tailstock with rotating quill (ANC-210DT) | - Transformer 380 V |

| - Automatic coolant lubrication system | - Working light |

| - Fanuc 0iT controller | - Tool box |

| - Manual operation | - Set of bolts |

| Additional options | |

|---|---|

| - Integrated spindle for the main spindle | - Voltage regulator |

| - C-axis drive turret | - Tool presetter |

| - Y1 axis: travel ±60 mm | - Automatic workpiece measurement device |

| - Y2 axis: travel ±40 mm | - Loading / unloading system |

| - Rear сhip сonveyor | - Measuring ruller |

| - Bar feeder | - Air cleaning device for chuck |

| - Finished parts catcher | - Automatic door |

| - Cutting, auxiliary tool | |