AKAYA- INNOVATION AND QUALITY CREATES FUTURE

| Machine features |

|---|

|

| Machine features |

|---|

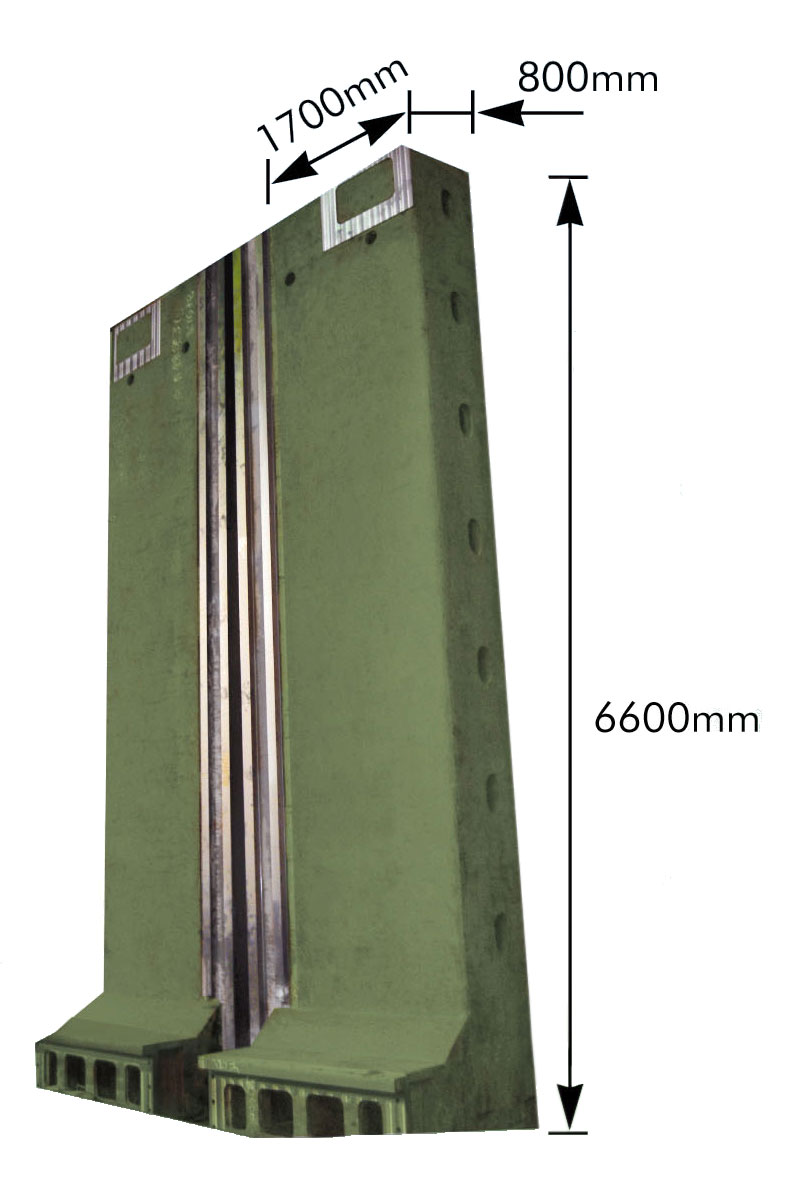

Large machines have a massive structure of the column, which provides the ability to process large and heavy workpieces

The ability to install 1 to 4 headstocks to ensure the effectiveness of machining of various workpiece shapes

| Parameters/Model | Unit | AYM -3020 |

AYM -4020 |

AYM -5020 |

AYM -6020 |

AYM -3025 |

AYM -4025 |

AYM -5025 |

AYM -6025 |

AYM -8025 |

AYM -10025 |

AYM -4030 |

AYM -5030 |

AYM -6030 |

AYM -8030 |

AYM -10030 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X Axis travel | mm | 3000 | 4000 | 5000 | 6000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Y Axis travel | mm | 2000 | 2500 | 3000 | ||||||||||||

| Z Axis travel (head) | mm | 300 (10HP) standart / 400 or 600 (15 HP) option | ||||||||||||||

| Distance between columns | mm | 2050 | 2550 | 3050 | ||||||||||||

| Spindle nose to table surface | mm | 1500 | 1700 standart / 2000, 2500 option | |||||||||||||

| Table (length) | mm | 3000 | 4000 | 5000 | 6000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Table (width) | mm | 1500 | 2000 | 2500 | ||||||||||||

| Spindle power (vertical) | HP | 10 (Standart)/ 15 (Option) | ||||||||||||||

| Spindle power (horizontal) | HP | 10 (Standart)/ 15 (Option) | ||||||||||||||

| Driving system | mm | Ball screw | Ball screw/Gear type | Ball screw | Ball screw/Gear type | |||||||||||

| Net weight | kg | 26000 | 29000 | 33500 | 37000 | 37000 | 45000 | 51500 | 56000 | 71000 | 88000 | 49000 | 55000 | 62000 | 80000 | 96000 |

| Machine length | mm | 8380 | 10980 | 12780 | 15000 | 8380 | 11000 | 12800 | 15000 | 19500 | 25800 | 11000 | 12800 | 15000 | 19500 | 25800 |

| Machine width | mm | 4500 | 5200 | 5700 | ||||||||||||

| Machine height | mm | 3880 | 4950 Standart/ 5400, 5900 Option | 5100 Standart / 5500, 6000 Option | ||||||||||||

| Parameters/Model | Unit | AYM -5035 |

AYM -6035 |

AYM -8035 |

AYM -10035 |

AYM -6042 |

AYM -8042 |

AYM -10042 |

AYM -12042 |

AYM -6050 |

AYM -8050 |

AYM -10050 |

AYM -12050 |

AYM -8055 |

AYM -10055 |

AYM -12055 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X Axis travel | mm | 5000 | 6000 | 8000 | 10000 | 6000 | 8000 | 10000 | 12000 | 6000 | 8000 | 10000 | 12000 | 8000 | 10000 | 12000 |

| Y Axis travel | mm | 3500 | 4200 | 5000 | 5500 | |||||||||||

| Z Axis travel (head) | mm | 300 (10HP) standart / 400 или 600 (15 HP) option | ||||||||||||||

| Distance between columns | mm | 3550 | 4250 | 5050 | 5550 | |||||||||||

| Spindle nose to table surface | mm | 2000/ 2500, 3000 (option) | 2000/ 2500, 3000, 3500, 4000 (option) | |||||||||||||

| Table (length) | mm | 5000 | 6000 | 8000 | 10000 | 6000 | 8000 | 10000 | 12000 | 6000 | 8000 | 10000 | 12000 | 8000 | 10000 | 12000 |

| Table (width) | mm | 3000 | 3200 | 4000 | 4000 | |||||||||||

| Spindle power (vertical) | HP | 10 (Standart)/ 15 (Option) | ||||||||||||||

| Spindle power (horizontal) | HP | 10 (Standart)/ 15 (Option) | ||||||||||||||

| Driving system | mm | Ball screw | Ball screw/Gear | Ball screw | Ball screw/Gear type | Ball screw | Ball screw/Gear type | Ball screw/Gear type | ||||||||

| Net weight | kg | 63000 | 73000 | 90000 | 110000 | 82000 | 105000 | 12800 | 152000 | 100000 | 112000 | 132000 | 152000 | 122000 | 143000 | 163000 |

| Machine length | mm | 12800 | 15000 | 19800 | 26000 | 15000 | 19800 | 26000 | 29500 | 15000 | 19800 | 26000 | 29500 | 19800 | 26000 | 29500 |

| Machine width | mm | 6300 | 7100 | 7800 | 8400 | |||||||||||

| Machine height | mm | 5600 standart/ 6150, 6650 (option) | 5600 standart/ 6150, 6650, 7150, 7650 (option) | |||||||||||||

| Standart systems and accessories | |

|---|---|

| - Machining zone cooling system | - Pneumatic tool lock system |

| - Working light | - Micro feeding adjustment |

| - Guidelines have plating Turcite-B | - Automatic lubricators for buttom guidelines |

| - Automatic hydraulic crossbeam lock | - Safety crossbeam cover |

| - Tool box | - Manual operation |

| Additional options | |

|---|---|

| - Custom made cutting and auxiliary tools | - Different spindle (15 HP) |

| - Workpiece for machining test | - Digital display device Fagor |

| - Machining heads | - Other accessories based on customer requirements |